USA

Quality and innovation for every work need

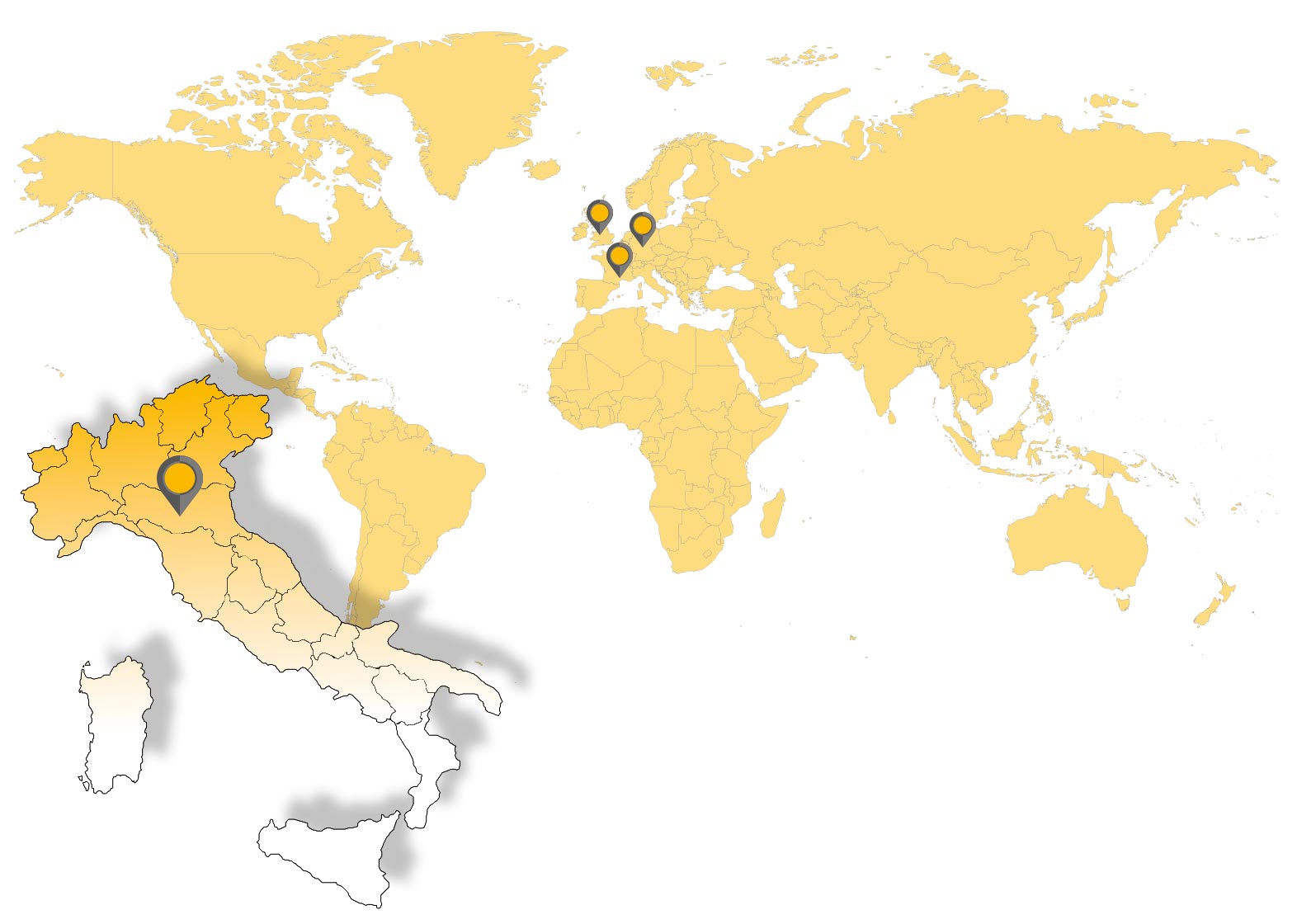

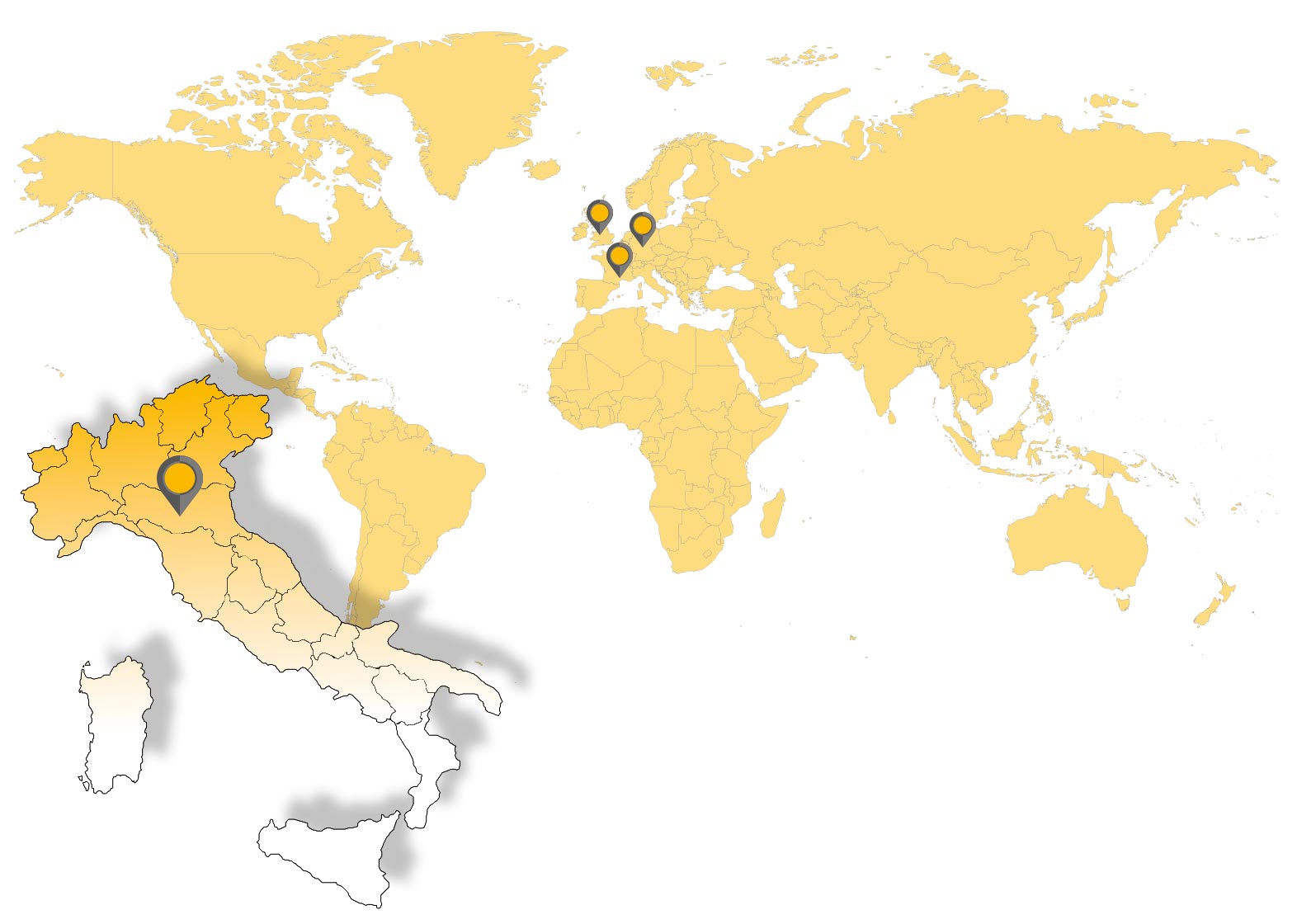

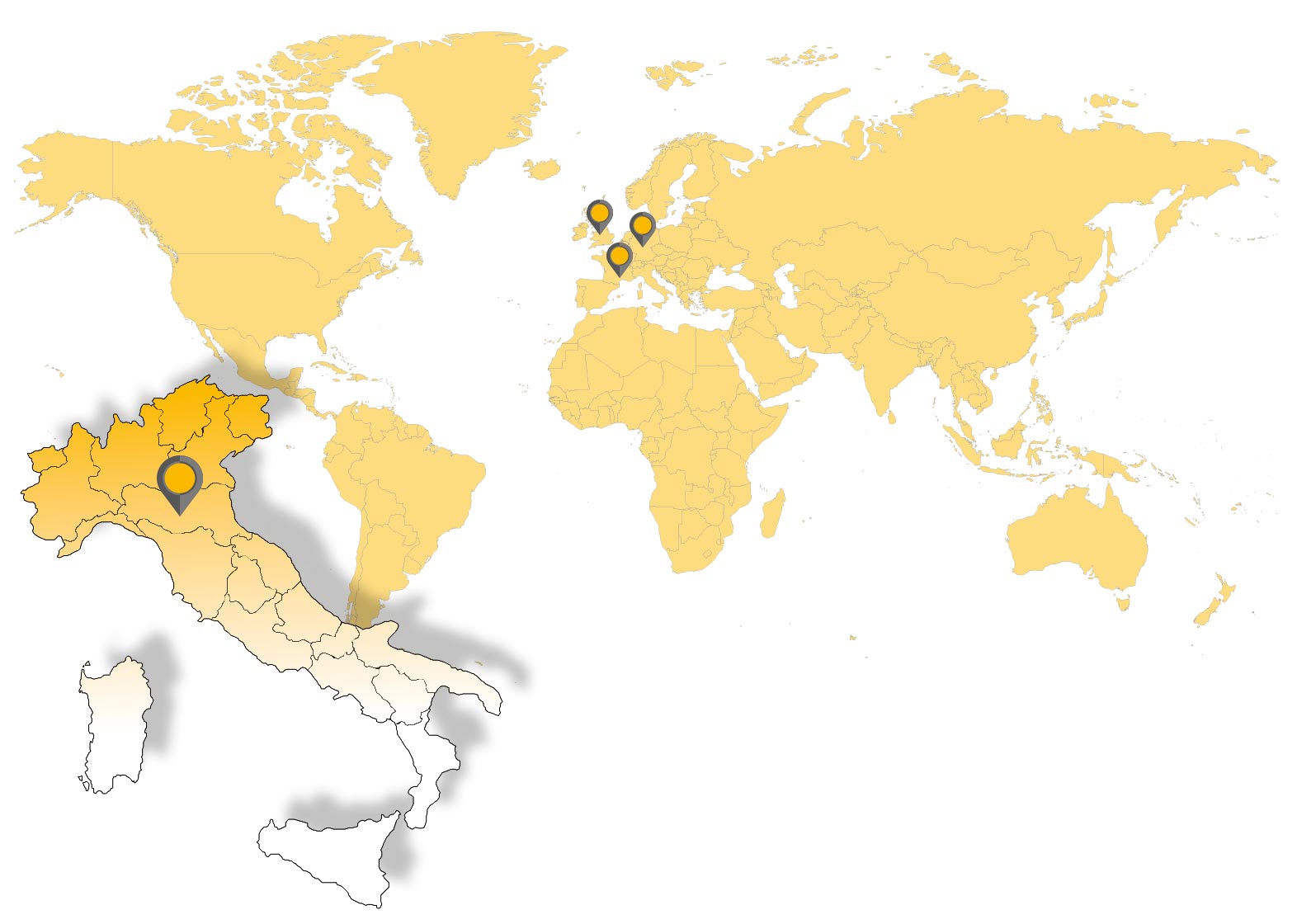

Italian know-how for the international market

Quality and innovation for every work need

Italian know-how for the international market

Quality and innovation for every work need

Italian know-how for the international market

1962

F.lli DIECI

1983

First range of telescopic handlers

1997

DIECI srl is established

1998

New S.I.R. range

2000

First Pegasus rotating telehandlers

2004

Mini Agri/Apollo

2007

Expansion and new headquarters

2012

Dieci goes international

2013

Pivot

2023

DIECI-e

1962

F.lli DIECI

1983

First range of telescopic handlers

1997

DIECI srl is established

1998

New S.I.R. range

2000

First Pegasus rotating telehandlers

2004

Mini Agri/Apollo

2007

Expansion and new headquarters

2012

Dieci goes international

2013

Pivot

2023

DIECI-e

1962

F.lli DIECI

1983

First range of telescopic handlers

1997

DIECI srl is established

1998

New S.I.R. range

2000

First Pegasus rotating telehandlers

2004

Mini Agri/Apollo

2007

Expansion and new headquarters

2012

Dieci goes international

2013

Pivot

2023

DIECI-e

Services

Services

Support

Spare parts

Maintenance

Warranty

Financial services

RMI

Services

Support

Spare parts

Maintenance

Warranty

Financial services

RMI

CONSTANT RESEARCH AND INNOVATION

Eima 2024 - Technical Innovation Award. FAST ATTACH

Eima 2022 - Technical Innovation Award. HYBRID BOOST SYSTEM

Eima 2020-2021 - Technical Innovation Award. ADAPTIVE LOAD SENSING (ALS)

CONSTANT RESEARCH AND INNOVATION

Eima 2024 - Technical Innovation Award. FAST ATTACH

Eima 2022 - Technical Innovation Award. HYBRID BOOST SYSTEM

Eima 2020-2021 - Technical Innovation Award. ADAPTIVE LOAD SENSING (ALS)

CONSTANT RESEARCH AND INNOVATION

Eima 2024 - Technical Innovation Award. FAST ATTACH

Eima 2022 - Technical Innovation Award. HYBRID BOOST SYSTEM

Eima 2020-2021 - Technical Innovation Award. ADAPTIVE LOAD SENSING (ALS)